Wire Processing

At PRF, we carry out processes like Spheroidization, Annealing, Pickling, Phosphating and Wire Drawing on various grades of steel with a monthly capacity of 2500 Tons for wire range 5 MM – 30 MM.

Tooling

In-house tooling enables us to develop new components in a short-lead time. At PRF, we have well-equipped tool room, aided with modern Vertical Machining Center and special purpose machines, to produce high quality dies.

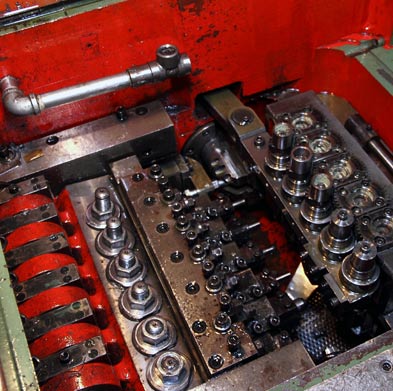

Cold Forging

State-of-the-art multi station cold part (7 stations) and bolt (4, 5 and 6 stations) formers enable us to produce critical and complex shaped components to a very high level of precision, ranging from 4-28 MM in diameter and 6-500 MM in length. Also, Cold Forging Presses and Trimming Presses with a total capacity of more than 2,000 Tons.

Thread Rolling

Well equipped with modern and high-speed machines from Taiwan of Chun Zu, Chien Tsai and Charng Guey make.

Thread rolling dies of OSG (Japan), Reed (U.S.A.) and TNP (Korea) are used to produce uniform threads with closer tolerances and better size control.

Heat Treatment

PLC controlled continuous mesh belt Carburizing, Hardening and Tempering Furnace of San Yung (Taiwan) ensures the high standards of quality. Carbon content of furnace atmosphere is closely controlled to produce a uniform product. Monthly capacity of 2000 MT.

Hot Forging

In house hot forging facility supported by Vertical Machining Center of YCM Taiwan enables us to produce sockets and housings of complex diameters.

Machining

To produce components with critical dimensions and close tolerances, latest and modern CNC Turning Centers and Ball Turning and Burnishing Machines of ACE Micromatic (India) have been installed.

Surface Treatment

We provide surface treatments, such as Zinc Plating, Zinc Nickel, Zinc Iron, Geomet and Encapsulation to attain high quality surface finish.